Diagnose Manufacturing Inefficiencies & Defects in Minutes, Not Weeks

Optimize factory operations and reduce defects with fast-turnaround analyses from digital workers.

The Overarching Problem:

You can’t spare months analyzing your data

When a defect hits, every hour counts. Lost materials, wasted production, and missed quotas stack up fast. But traditional Root Cause Analysis takes weeks, and the results come back in data science terms that plant teams can’t use at the moment.

Data Silos, multiple SaaS tools and static dashboards are slowing your teams down.

“We typically scale [analysis] by hiring a lot of people. With causaLens agents, we can do this in a day, not a month, saving time for treatment for the patients and ROI for the company.”

Juan Carlos Araque, Principal Scientist

Johnson & Johnson

The Solution:

Root Causes at your fingertips

Put the power of Root Cause Analysis in the hands of the people who need it. With causaLens digital workers, plant teams can ask questions in natural language and receive accurate answers quickly, in plain English.

Our Digital workers plug into your live data sources and extract insights in real time. Say goodbye to the operational chaos with multiple tools & dashboards.

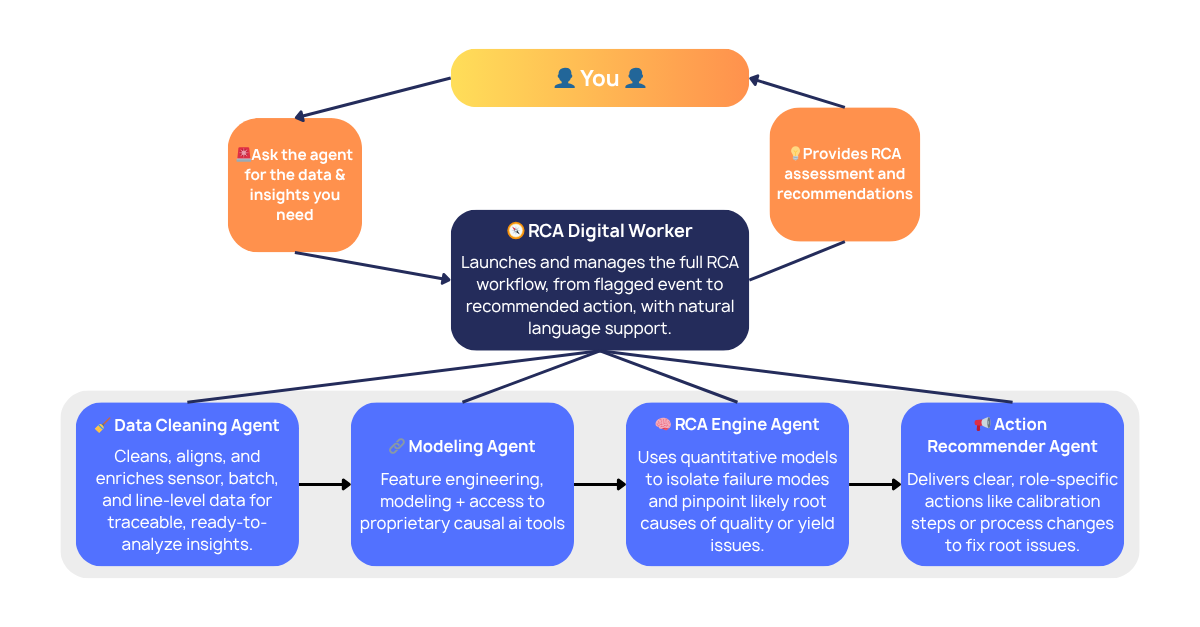

How it Works

When you discover a failure or inefficiency in your process, you submit a request to the RCA orchestrator agent in natural language (or trigger it from another system).

The orchestrator determines what will be necessary to clean the data, model it, determine the most likely failure, and communicate the results back to you. It assigns the work to specialized agents for each of these tasks, and together they return a quantitative RCA in a fraction of the time of other options.

Root Cause Analysis Digital Worker In Action

What the agent does:

Identifies the top three root causes for faults in a specific manufacturing batch.

Analyzes, requests clarifying information, and suggests recommended actions to take right now to prevent future failures.

Autonomously visualizes the recommended adjustments for the given parameters.

Related Resources

Customer Story

See how Johnson & Johnson scaled decision-making in drug manufacturing.

Customer Story

How a major manufacturer boosted performance with digital workers.

Demo Hub

Explore our technical and use case demos by visiting our Demo Hub to discover what's possible.